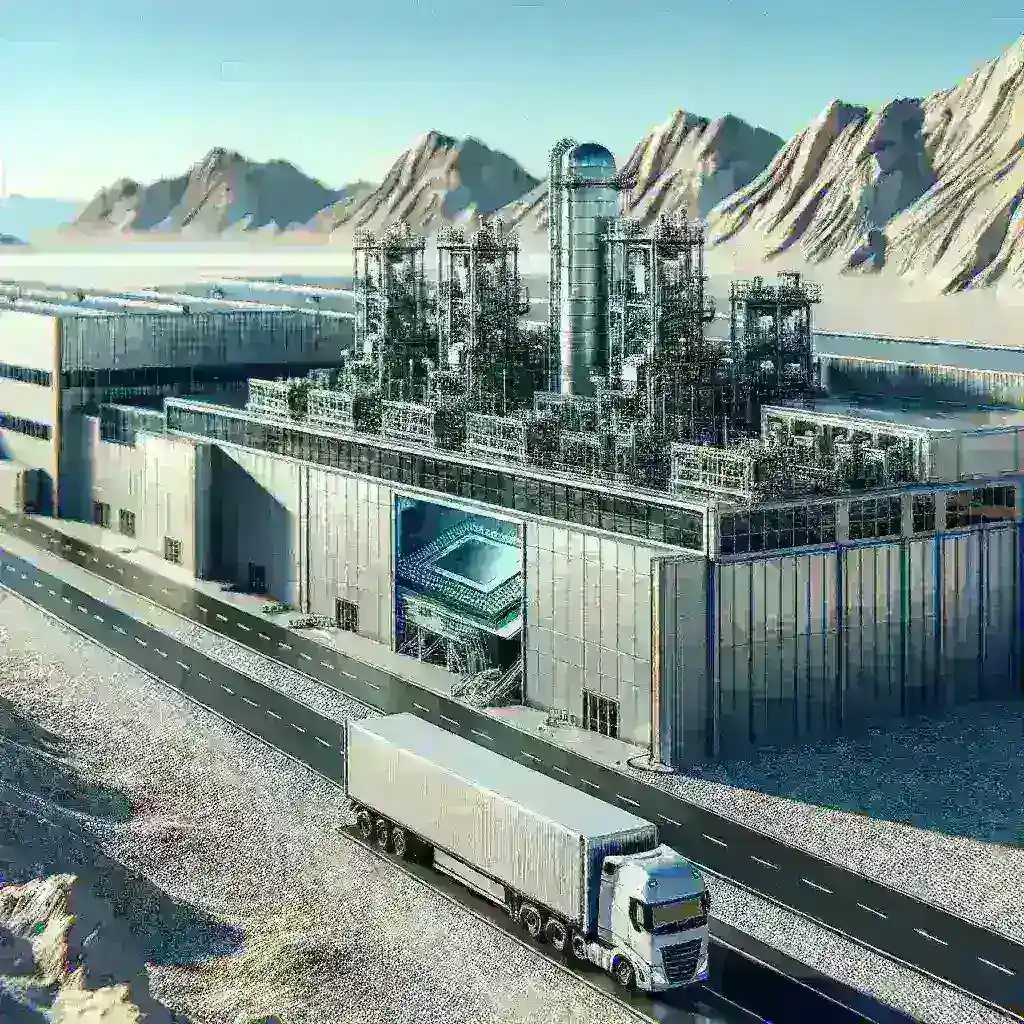

TSMC Arizona Fab Begins Shipping Chips to U.S. PC Makers

Introduction

The semiconductor industry is undergoing a transformative phase, and one of the most significant developments in recent times is the commencement of chip shipments from Taiwan Semiconductor Manufacturing Company (TSMC)’s Arizona fabrication plant. This pivotal moment marks a new chapter for U.S. PC manufacturers, promising to bolster local production capabilities and reduce reliance on overseas supply chains.

The Significance of TSMC’s Arizona Plant

Established to enhance the U.S. semiconductor ecosystem, TSMC’s Arizona fab is poised to play a crucial role in addressing the growing demand for chips across various sectors, particularly in personal computing. By manufacturing advanced semiconductors on American soil, TSMC aims to provide a steady supply of chips to domestic PC makers while simultaneously promoting technological innovation.

Historical Context

The decision to build a fabrication plant in Arizona was influenced by several factors, including geopolitical tensions, the COVID-19 pandemic’s impact on global supply chains, and the urgent need for localized manufacturing. Historically, the semiconductor industry has been heavily concentrated in East Asia, leading to vulnerabilities in the supply chain. TSMC’s investment in Arizona represents a strategic shift towards decentralization, enhancing the resilience of the U.S. semiconductor supply chain.

What Does This Mean for U.S. PC Makers?

With the Arizona fab now operational, U.S. PC makers can expect:

- Improved Supply Reliability: Local production reduces lead times, ensuring manufacturers can meet consumer demand without delays.

- Enhanced Customization: Proximity to manufacturing allows for better collaboration between chip designers and PC manufacturers, enabling tailored solutions for specific market needs.

- Cost Efficiency: Reduced shipping costs and tariffs can lead to lower overall production costs for U.S. manufacturers.

Future Predictions

As TSMC ramps up production at its Arizona facility, several future trends are likely to emerge:

Increased Competition

With TSMC’s entry into the U.S. market, other semiconductor firms may accelerate their plans to establish local fabs, intensifying competition. This could lead to innovation and better pricing strategies within the sector.

Expansion of the U.S. Semiconductor Workforce

The establishment of the Arizona fab is expected to create thousands of jobs, not just within the facility but throughout the supply chain. Educational institutions and training programs may also evolve to meet the demand for skilled labor in the semiconductor industry.

Potential Collaborations

As local chip production becomes a reality, partnerships between TSMC and U.S. tech companies may flourish, leading to groundbreaking advancements in technology. This collaboration can facilitate the development of cutting-edge devices that leverage the latest semiconductor innovations.

Challenges Ahead

Despite the promising outlook, several challenges may impact the success of TSMC’s Arizona fab:

Infrastructure and Resources

The semiconductor manufacturing process is resource-intensive, requiring substantial water and energy. Ensuring sustainable practices while scaling operations will be crucial for TSMC and its stakeholders.

Geopolitical Risks

As tensions escalate on the global stage, including trade disputes and supply chain disruptions, TSMC must navigate these challenges while maintaining production efficiency.

Real-World Examples

Other tech giants have also recognized the importance of localizing semiconductor production. For instance, Intel’s investment in new facilities across the U.S. highlights a collective industry shift towards enhancing domestic manufacturing capabilities.

Expert Opinions

Industry experts have lauded TSMC’s decision to establish a fab in Arizona, citing it as a significant step towards securing the U.S. semiconductor supply chain. According to Dr. Lisa Su, CEO of AMD, “The establishment of local manufacturing will not only create jobs but also foster innovation that benefits the entire tech ecosystem.”

Conclusion

The commencement of chip shipments from TSMC’s Arizona fab to U.S. PC makers signifies a vital advancement in the semiconductor landscape. As the industry evolves, the implications of this development will resonate through various sectors, ultimately shaping the future of technology in the United States. With enhanced supply chains, increased collaboration, and a commitment to innovation, TSMC’s Arizona facility is set to become a cornerstone of the U.S. semiconductor sector.

Leave a Comment